What’s IPC?

It’s a device that monitors in real time the behaviour of the "inductor-heated part system" while heating.

How is it possible to get this task?

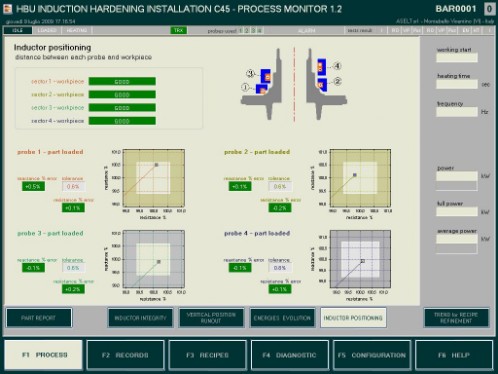

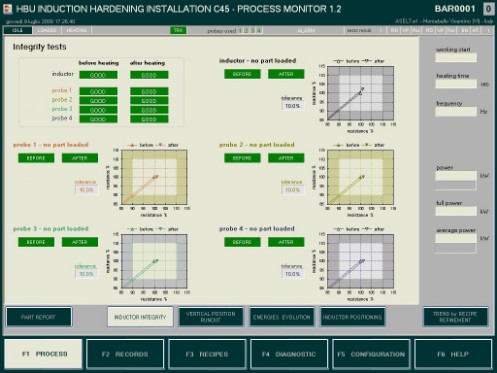

By means of some signal captors built-in with the inductor windings, IPC measures:

- digital electromagnetic parameters related to the relative distance in between inductor sectors and heated part sectors in front

- analog electromagnetic parameters related to the heating power of each one inductor sector

The two sets of parameters of the part found "good" by metallurgical laboratory are recorded in the computer equipping the IPC.

They create a "virtual master" of heating process and tolerances are established.

The sets of measured parameters of the parts in production are compared, every heating shot, with the "virtual master".

When actual part heating process, namely the sets of parameters measured along the heating time, is found out of tolerance, part is rejected and an alarm is generated.

Taking account that:

- a "gage" for controlling induction hardened case dept and its metallurgical structure doesn’t exist

- the only reliable check is by cutting part and proceeding to metallurgical laboratory test

IPC is actually the ultimate device for 100% induction heating for hardening quality control.

See specific documentation for details.