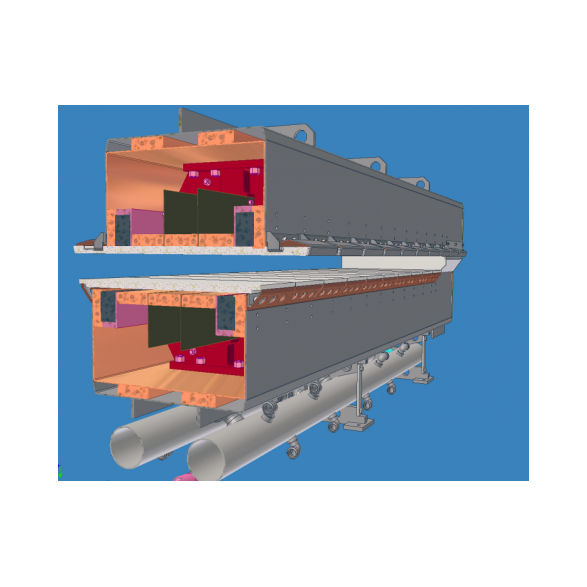

Heavy duty inductors

Upon request Aselt srl may supply "Heavy duty inductors" with windings made by silver-bearing copper.

Copper windings of heavy duty inductors at any heating operation reach easily about 200 ºC temperature or even more.

Look at the following table comparing creep rupture of usual electrolytic copper ( TP Tough pitch ) with silver bearing 0,1%Ag oxygen free copper. Both material being annealed.

Testing stress at 200 ºC |

Tough pitch |

Silver-bearing copper 0,1% Ag |

newton/mm² |

Hours to failure |

Hours to failure |

165 ( about 16,5 kg/mm² ) |

0,5 |

15 |

155 ( about 15,5 kg/mm² ) |

2,5 |

80 |

138 ( about 13,8 kg/mm² ) |

10 |

>1000 |

124 ( about 12,4 kg/mm² ) |

40 |

>1000 |

Copper windings are stressed by electro-dynamic forces due to the current flowing in the windings, dilation contrasted by mechanically constraints keeping shape and cooling water pressure.

It’s very difficult to know exactly the actual stress of the copper of an inductor when working.

Stresses too high are recognized by short inductor life.

The mechanical superiority of silver-bearing copper 0,1%Ag it’s absolutely evident.

SPECIAL INDUCTORS